The World’s First Freeform 3D-Printed House Makes the Jetsons Look Amish

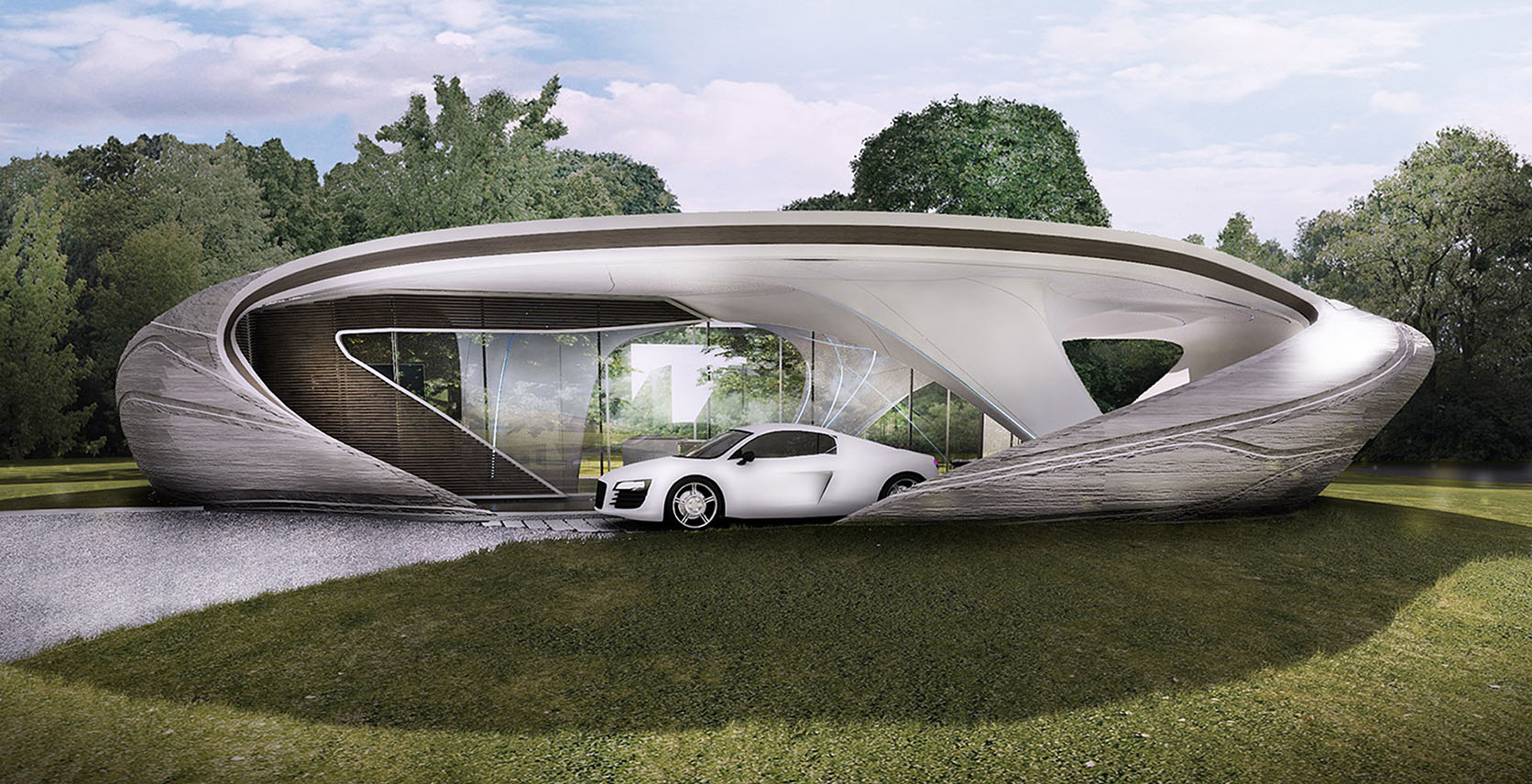

The wave of the future has hit us hard, and surfing those waters is WATG’s freeform Curve Appeal 3D-Printed House. The first of its kind, this 1000 square-foot residence is built for a king — in the year 3018.

Designed to be connected with nature, it features large windows, maximized natural light, and solar carving, making it net-zero-energy. In other words, this abode is as green as they come.

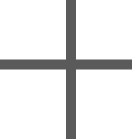

Don’t think it can get any more out there? Take a peek inside. Inspired by Case Study Houses of the 1950s, the curved house has a minimalist, modernist aesthetic, with an open concept and glazed floors connected by natural materials. That countertop takes modern to the next level.

The project won first prize in the Freeform Home Design Challenge in 2016, and is now under construction. The challenge: rethink the aesthetics, ergonomics, construction, building systems, and structure of a traditional single-family home. Challenge nailed.

You may be wondering: is this entire house 3D printed? It is not. In fact, only the curving frame and braces are to be 3D freeform printed, mostly likely from a fire-resistant gypsum — a lightweight building material ideal for open-space structures. In other words, there are fewer braces aerodynamically placed to allow for more space on the inside using a minimal amount of materials.

The Curve Appeal house is set to be built by late 2018, in a beautiful woodsy lot steps away from the Tennessee River in Chattanooga. 3D printing’s come a long way from this.