The first thing that comes to mind when you think of flat-pack furniture is almost certainly what you’ve bought and screwed together from the most famous furniture brand in the world — that blue and yellow giant. And with this, perhaps, come some preconceived notions about the durability (or the lack thereof) of flat-pack furniture. “Of course, it was a concern to start with — that we would be seen as an extension of Ikea,” says Henrik Taudorf Lorensen, whose brand Takt is redefining the flat-pack space by combining its environmental benefits with something it’s been missing for a long time: high-quality construction and a sense of craft.

Founded in 2019, the Danish brand was first envisioned as a sustainable furniture label in a wasteful industry. “Furniture may not be the [worst offender] when compared to flying airplanes or the fashion industry, but it’s up there,” says Lorensen, a trained physicist who previously worked at Bang & Olufsen and Lego.

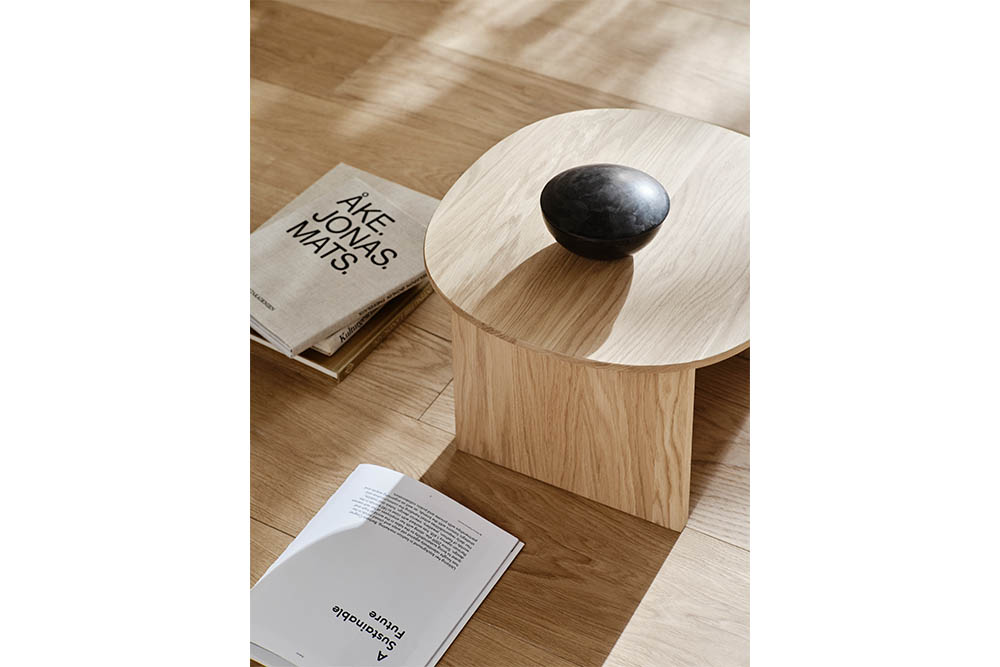

While Takt’s output is archetypally Scandinavian — its chairs, tables, and benches are honest and elegant — its sustainability efforts are anything but conventional. A certified B Corporation, Takt uses wood sourced exclusively from sustainable forests. The brand further offsets its already rather modest carbon footprint by using flat-packing to minimize emissions when shipping its products around the globe. The idea behind the latter is simple: a piece of furniture disassembled into its component parts is more efficient than a fully assembled one when it’s being packed onto a plane, truck, or ship. The benefits, explains Lorensen, go even further. A piece of furniture that can be broken down into its component parts ultimately minimizes materials waste, as damaged parts can easily be replaced.

While Takt has made quite a splash in the industry since its launch, has it successfully debunked the claim that flat-pack furniture is only for the budget-minded, or that it lacks craft and quality? Lorensen certainly thinks so. “When you unpack most ready-made furniture, most pieces don’t look too nice underneath, because the designer or production company knows that’s where you can cut corners. But we know people are going to feel each component in their hand and turn them around and inspect every corner,” says Lorensen. “[With our designs], you feel the solid oak wood in your hands. The pieces glide and connect in a very nice way. So that’s our ambition: can we make even the assembly process into a reassurance that you’ve made the right decision?”