At Gillette’s World Shaving Headquarters, Enough Wonders to Impress Willy Wonka

If Roald Dahl had written an adventure revisiting Charlie Bucket as an adult — persistent five o’clock shadow and all — the Gillette World Shaving Headquarters could have served as a compelling setting.

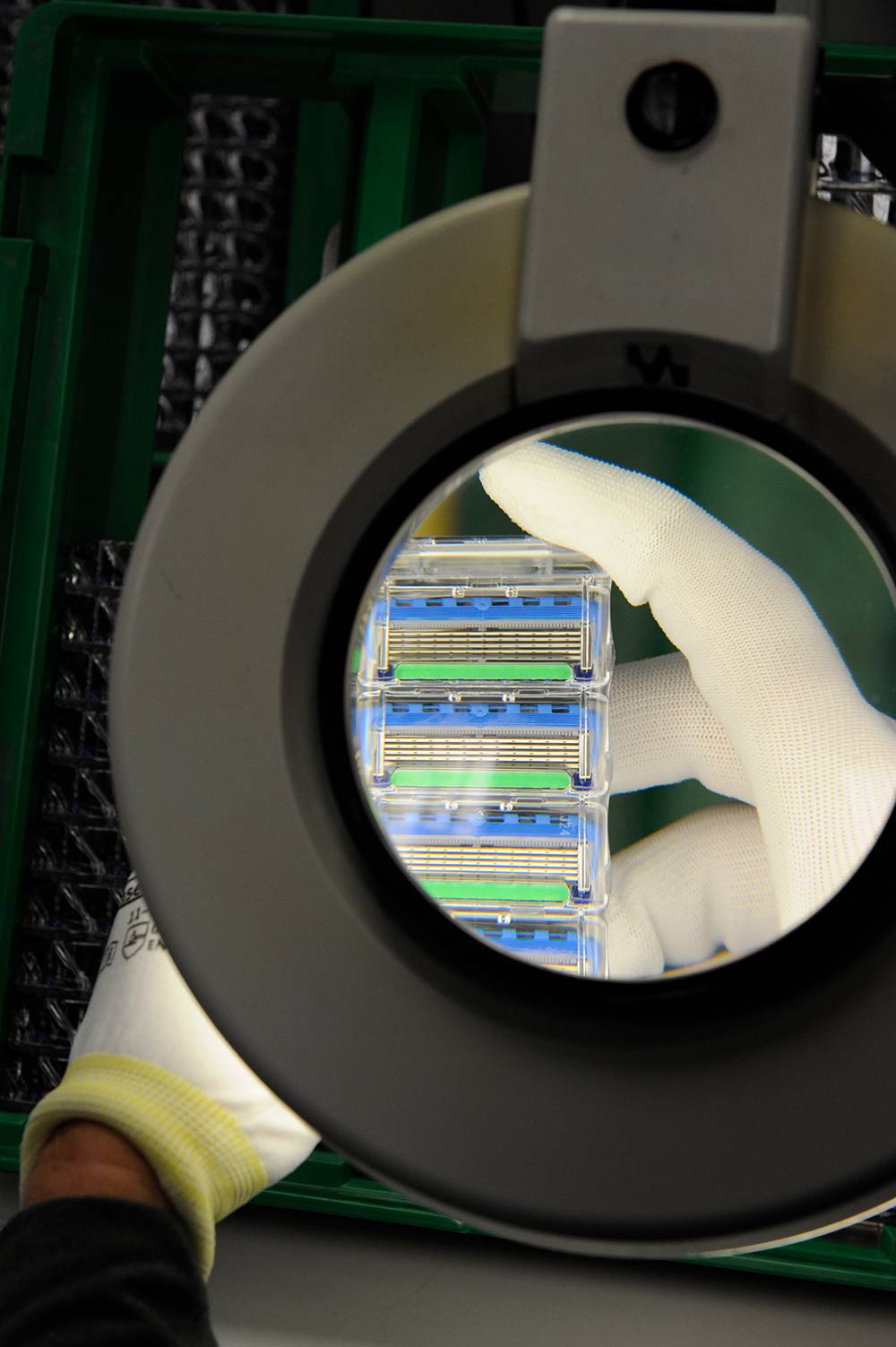

Granted, there are no Oompa Loompas on my tour of the facility. But there are other spectacles, like a virtual-reality theatre that allows me to experience a shave from the perspective of my beard hair. Billions of blades — each one thinner than a surgeon’s scalpel, and subject to 60 quality checks before leaving the factory — originate from this production plant every year. In light of Gillette’s new move to lower its prices on Fusion and Fusion ProGlide cartridges, the engineering wizardry on display here stresses just how much value is packed into each one of the company’s products.

Located in Boston’s South End, the forty-plus-acre campus base dates back to 1904 — shortly after Gillette was launched by businessman King C. Gillette in collaboration with MIT engineer William Nickerson. (Their first razor was introduced in Canada two years later.) Near the entrance, a timeline charts various chapters in the brand’s history, spotlighting a few fun moments along the way — a framed, diamond-encrusted razor created for David Beckham for Father’s Day 2005, for instance.

Flash forward to 2017, and Gillette’s research and development teams are continuing the company’s tradition of innovation. One lab-coated scientist tells me that the average man takes 170 strokes to shave his face, with the most challenging of those proving to be around the jawline. Hence the development of Gillette’s Fusion ProGlide with Flexball Technology, which mounts blade cartridges on a pivoting mechanism that twists and turns to effortlessly navigate a face’s contours. Best of all, with Gillette recently lowering Canadian prices on its cartridges in response to customer feedback, this top-tier shaving system is now more affordable than ever.

That said, Gillette’s team is dedicated to incorporating cutting-edge technology in their lowest-cost single-use razors, too — ensuring that every one of its customers enjoys optimal closeness and comfort. A product developer showcases this by running a low-cost Sensor 3 disposable along a ridgy sheet of cardboard. Thanks to springs on the back of each blade, the razor navigates over bumps with little to no resistance.

With a new appreciation for each of these razors, it’s next time to head to the actual factory and watch the designs come together. Throughout several stadium-sized rooms of humming machinery, plastic handles are moulded; steel sheets are heated, cooled, and then coated in a “secret sauce” that makes them extra-durable; and cut blade strips are ground into precisely beveled arches ready to effortlessly slice through whiskers. Self-driving robots whizz all around the perimeter, stopping at each station to collect and deliver parts of a grooming product that has become a fixture on bathroom sinks all around the world.

For all of the studies that Gillette’s team cites throughout my visit, one stands out: if given the chance, 95 per cent of men would not take a pill to remove their facial hair. The takeaway: shaving is not a nuisance. Rather, it is a ritual that, with a cleverly designed, finely crafted, well-priced tool in hand, can be as satisfying a part of one’s day as dessert. And Charlie thought chocolate was impressive.